Seed Decorticator, Peanut Shellers, Peanut Shelling Machine

The peanut is not only an important economic crop but also a kind of plant that contains nutritional value. There are large quantities of peanuts used for exporting and food processing in all over the world, so the development of the peanut shelling machine was very important. We are one of the pioneers who produce peanut processing machines, and we have many exporters.

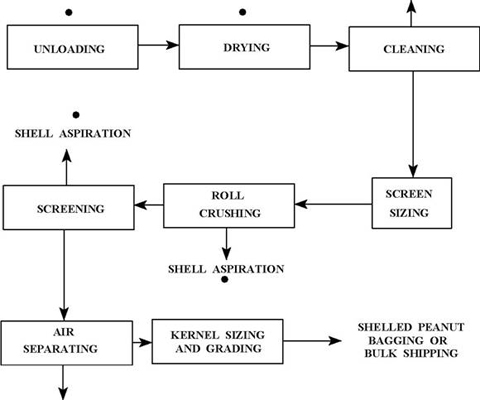

DECORTICATING ASSEMBLY LINE FOR GROUNDNUT SEED

Movable Peanut Sheller

This peanut sheller has large, medium, and small models. It adopts the principle of shelling with a screw pole and grid bar concave board. Its features include compound double shelling, high shelling ratio, low cracking ratio and human resources saving. etc. It can be applied to shelling peanuts of different regions and varieties.

|

Technicial parameter | |

|

Capacity (kg) |

500-800 |

|

Voltage(V) |

380 |

|

Power(KW) |

2.2 |

|

Size(mm)L*W*H(As weight) |

1500*800*1500 |

Peanut Shelling Machine (Combined)

This type peanut shelling machine mainly contains 3 parts, the destoner for peanuts, conveyer, and the peanut sheller. It features a compact structure, stable operation and low noise. One of the advantages of the peanut shelling machine is that the conveyer part is effective and economical. The peanuts can be conveyed by the machine-made wind directly. After being put into charging spout, the peanut automatically enters into decorticating room composed of two friction rollers, removing the skin of the peanut so as to produce peanut without red seed color.

Peanut Shelling Machine

|

Model 5XF3000C peanut cleaning machine |

Model 6BH-3000C peanut shelling machine | ||

|

Output |

3000kg/h |

Output |

3000kg/h |

|

Clean degree |

>= 97.5% |

Shelling ratio |

>= 98% |

|

Loss ratio |

<=0.5% |

Crushing ratio |

<=5% |

|

Power |

7.5kw,2grade |

Clean degree |

>= 99% |

|

7.5kw,6 grade |

Loss ratio |

<=0.5% | |

|

Total weight |

980kg |

DAMAGE RATIO |

<=4% |

|

Operators |

2 man |

Power |

5.5kw(4 grade or 6 grade) |

|

Dimension |

3120×1100×2750 |

Total weight |

1080kg(without motor) |

|

Operators |

2~4man | ||

|

Dimension |

2540×1360×3000 | ||

Worker put peanut in shell into dehuller,firstly,the peanut in shell fall into wide veins bar,the shell will be breaked by the rubbing from running veins bat and fixed bar concave bat,second, the peanut kernel and shell will fall into bar net,then into the wind passage,the shell be cleaned out machine by wind.the peanut kernel and a some small size peanut with shell fall into the specific gravity selecting sieve,through filtrating,the peanut kernels will be sent out from exit,the small size peanut with shell will be put into conveyer,then be sent into thin veins bar for second shelling,finally, the peanut all will be sheeled.

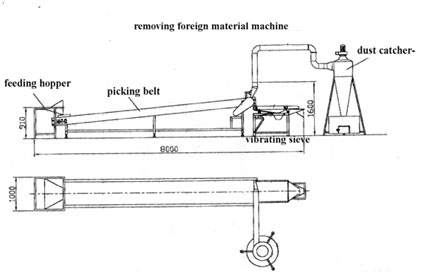

Peanut Blanching Unit

The beginning of this line is from roasted peanut kernel with red skin, through the elevator conveyor, peanuts enter into the feeder, and distributed averagely by 3 tubes. Then the peanuts automatically fall down then blanching room which is composed of two sand rollers, Under the function of roll's friction and rotating, the red skin is taken away, then light red skin is sucked by air fan, collected by first cyclone system, finally blanched white peanut kernel fall down to the selecting conveyor.

We design the selecting conveyor is 6M length usually, it can be done according customer's requirement. On this conveyor, the workers pick out the un-blanched or mildewed peanuts separately, the unblanched peanuts will be processed again, the entire white peanut kernel finally is put through the vibrating separator to make the final clean, here the second cyclone system will suck the red skin again to ensure there is no red peeler then go to packing step.